The chassis has been TIG welded and is one solid piece.

The chassis is surprisingly light for its size.

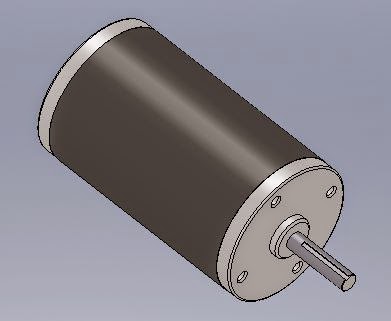

Both the left and right side drivetrains have been assembled and the chains/sprockets are set up to reduce the rpm values coming directly out of the 12V DC motors into a more practical and easier to control speed.

This is the basic set-up of the robot (just the drivetrain mounted to the chassis). Although the chassis was

very lightweight, the addition of the drivetrain makes the robot much heavier, almost too heavy to lift.

To power the robot we have taken two large 12V batteries and connected them via 6" bolts from lead to lead in parallel, then duct taped so they stay together indefinitely. This gives us twice the available amperage thus doubling our battery life.

(Running these in parallel is important because if we ran them in series we would have doubled the

voltage to 24V, which could result in the failure and destruction of several components of the robot.)

For safety and piece of mind we are going to run the power from the batteries to this 120A circuit breaker before it goes to the motor controller. This will allow us to simply push a button to kill the power to the system so we don't have to scramble to disconnect the battery leads if something bad starts happening.

We decided to power the Arduino board itself separately from the rest of the robot as a secondary security measure to make sure the robot doesn't start moving if the main 120A breaker is left on. We will have a 9V battery attached to the drum plug input connector on the Arduino with a simple toggle switch spliced into the positive wire.

.jpg)